Printed Electronics use digital manufacturing to pattern substrates with diverse electrical properties. nScrypt’s 3Dn Series conformally print antennas, resisters, inductors, capacitors, and interconnects on flexible, rigid, flat, curved, doubly curved, and even random 3D shapes. nScrypt’s patented SmartPump™ microdispensing tool head prints passives with more than 10,000 commercially available materials.

By mixing, matching, layering, and patterning from a virtually unlimited materials palette, the design engineer can use the 3Dn Series to print sensors, antennas, batteries, electroluminescent lighting, and other electronics on flexible substrates or existing structures of any shape. The SmartPump™ can also print to actives, including bare die or even thinned bare die.

Such capability enables the design engineer to manufacture highly complex printed circuits on virtually any flexible or existing structured surface.

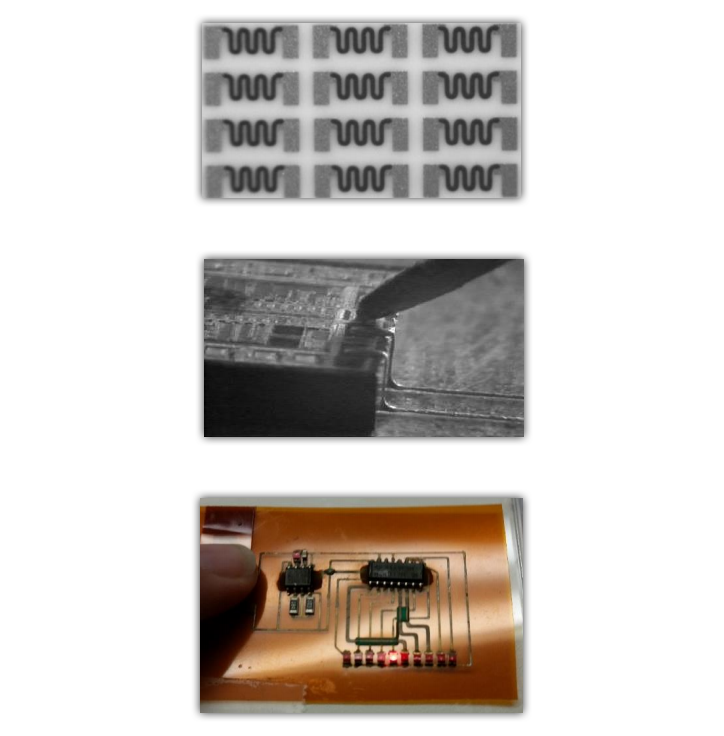

The photos here show (from top to bottom): 1) printed resistors, 2) printing to bare die, 3) printed circuit using lumped elements.

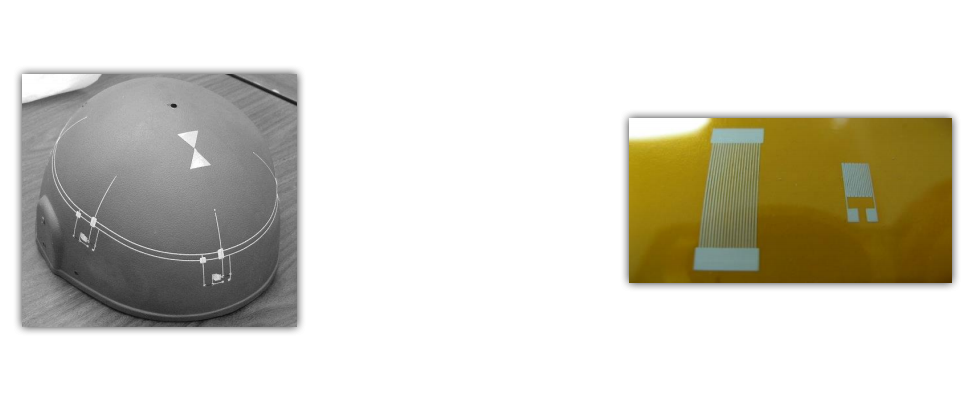

With the flexibility of the patented SmartPump™ and the 3Dn Series platform’s high-precision motion control, the design engineer can conformally print highly complex patterns and circuits on any surface. For example, the photo shows a roughly surfaced Kevlar helmet with prints along the top and around the sides.